Aircraft Wire Harnes Assembly

American precision assemblers built a custom wire harness from 20 awg teflon insulated wire for the aerospace industry.

Aircraft wire harnes assembly. To begin the process of building this product we first gathered all parts and tools as required. Avionics wire harness shop we now have a harness assembly shop providing avionics wire harnesses for the experimental market ranging from single avionics units to custom coax cable assemblies to complete panel wiring systems. In response the federal aviation administration faa issued the 251700 series of regulations covering the design manufacture and. It all starts with wire miles of it.

All are trained for many weeks on our assembly processes. Investigations found several common factors that could degrade the electrical wiring interconnection system ewis of an airplane over time. The cables are bound together by a durable material such as rubber vinyl electrical tape conduit a weave of extruded string or a combination thereof. Yearly recurring training ensures that they maintain their skill level and expertise.

In the late 1980s a series of accidents and incidents raised concerns about the safety of electrical wiring in aircraft. Most of our workforce is comprised of electrical assemblers. That tkt will be used throughout the aircraft with some exceptions such as rf cables and teflon insulated wire in boxed assemblies. This wire harness is currently being used for aircraft bulkhead lighting.

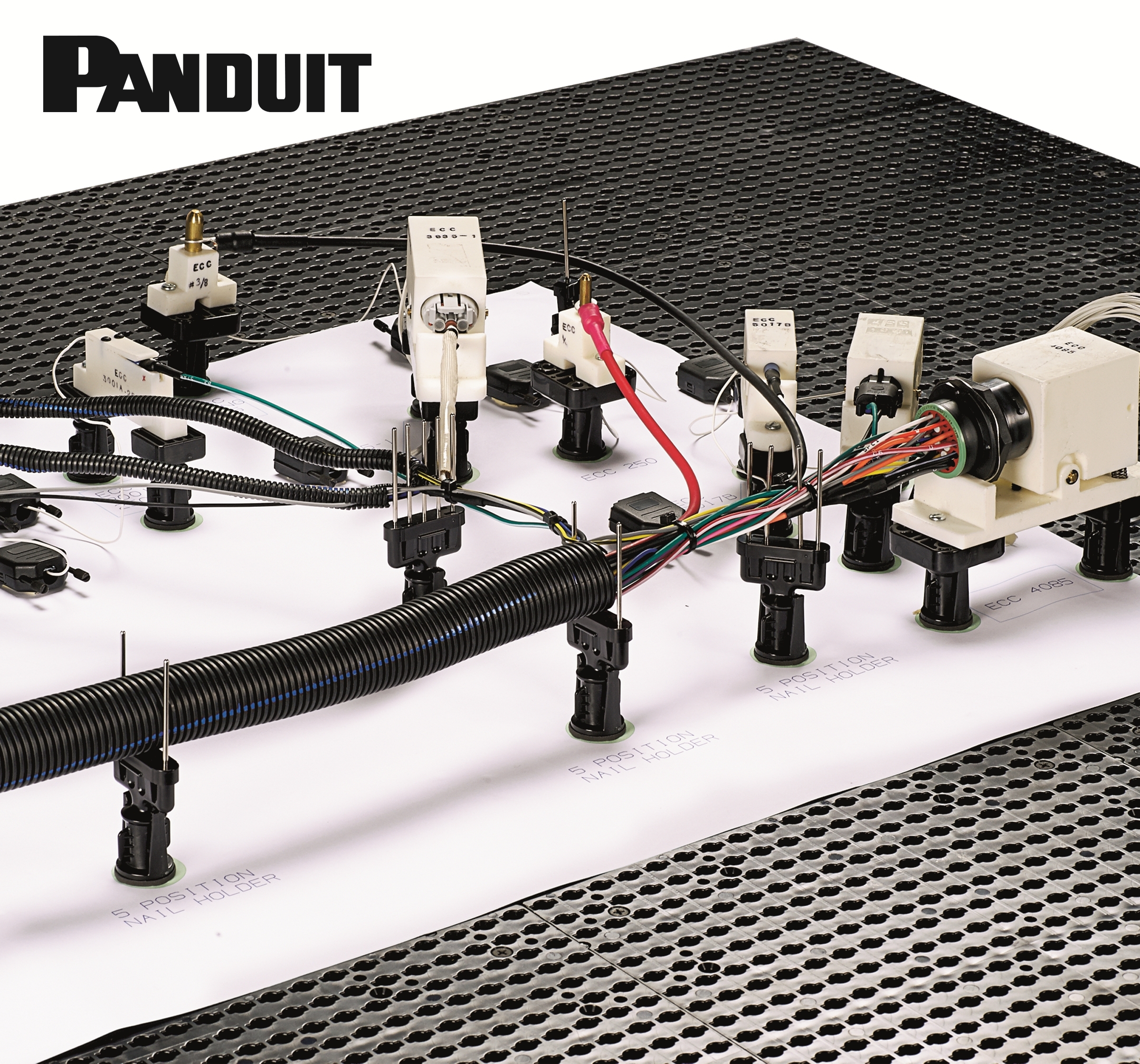

Harness board accessories tijuana mexicali tecate ensenada san luis rio colorado panduit duration.