Barber Coleman Actuator Wiring

For high temperature applications steam or very hot water use the av 601 valve linkage extension.

Barber coleman actuator wiring. Ing bracket and wiring harness consult the barber colman dyna distributor or dealer for installation kit information see the typical wiring for 1 2 4 or 6 dyna governor systems shown on pages 10 through 15 of this manual important things to follow when making an installation. Page 5 lowmedium torque actuators damper linkage assembly caution. Allow six inches clearance above the actuator wiring compartment. Figure 1 shows proper mounting of the barber colman actuator 1 to its mounting bracket 2 and proper mounting of the control linkage assembly items 4 6 and 8 between the actuator lever 3 and engine speed control lever 7.

If you are not getting a result type the first 3 or 4 digits an you will see a range of parts we have online. The damper must not be mechanically stopped before the actuator has reached its electrical limit of travel or permanent damage can occur to the actuator. Find a wide range of barber colman actuators motors controllers sensors switches and other miscellaneous parts. Note the e 361 has a 225 amp current limit.

Actuator selection tables below with 600 suffix have the cp 8301 120 factory installed. For compact actuation of 12 through 1 14 barber colman valves. The cp 8391 91x series have a fixed r ange of 4 to 20 madc to drive the actuator full stroke. Search for your barber colman actuator.

Procedure actuator may be used in damper and valve control applications. What barber coleman told me to do on the heating actuator doesnt work. They said the blue wire should always be hooked up between the duct stat and actuator break the red and yellow wire between the duct stat and actuator via the control relay connect the red and yellow wires together short to the actuator via the control relay. If an am type mounting bracket is not used the base of the actuator may be used as a template for marking mounting holes.

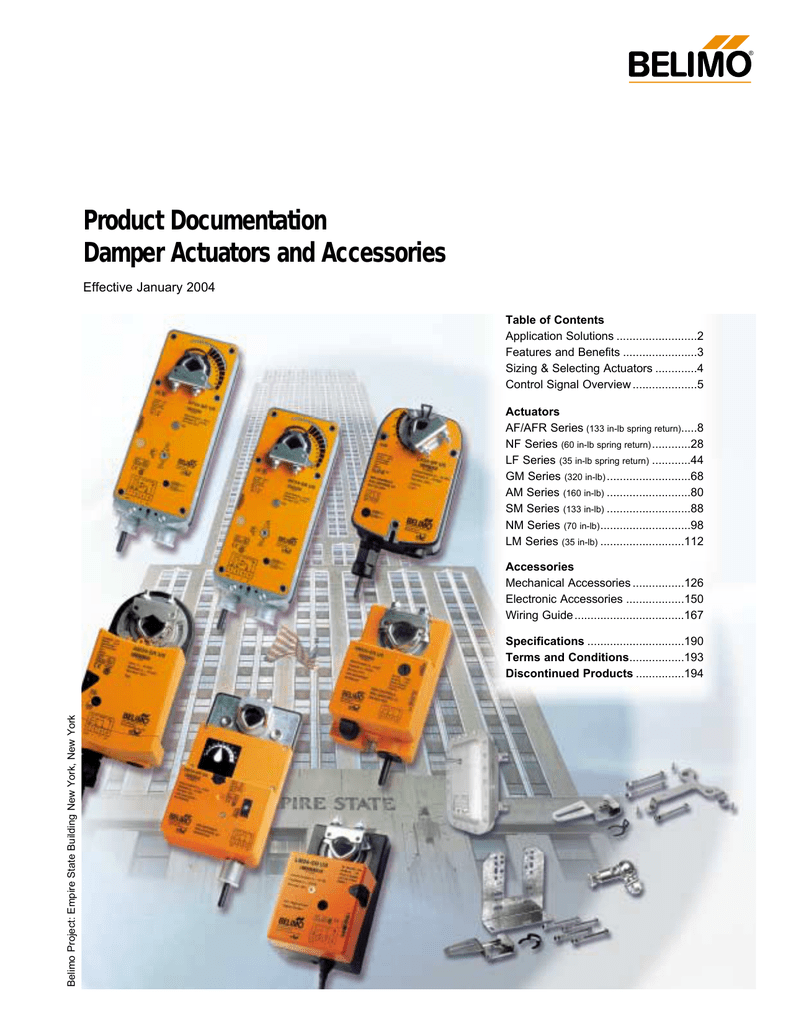

Barber colman round beercan actuator accessories. Replacing an obsolete barber coleman woodward speed controller with precision governors e 361 controller on engines with a zenith carburetor and integral throttle actuator. When applying one of the beercan electric actuators above as a damper actuator they must be ordered with the damper linkage if its for something other then direct replacement. Used for the barber colman actuator.

Barber colman oval pneumatic valve actuator. Ado not connect the control box connector to the wiring until. For new installations the av 400 linkage kit is required. All cp 8301s have a fixed span of 3 vdc to drive the actuator full stroke and a start point adjustable from 2 to 12 vdc factory set 6 vdc.