Diagram 3 Wire Heat Trace Cable

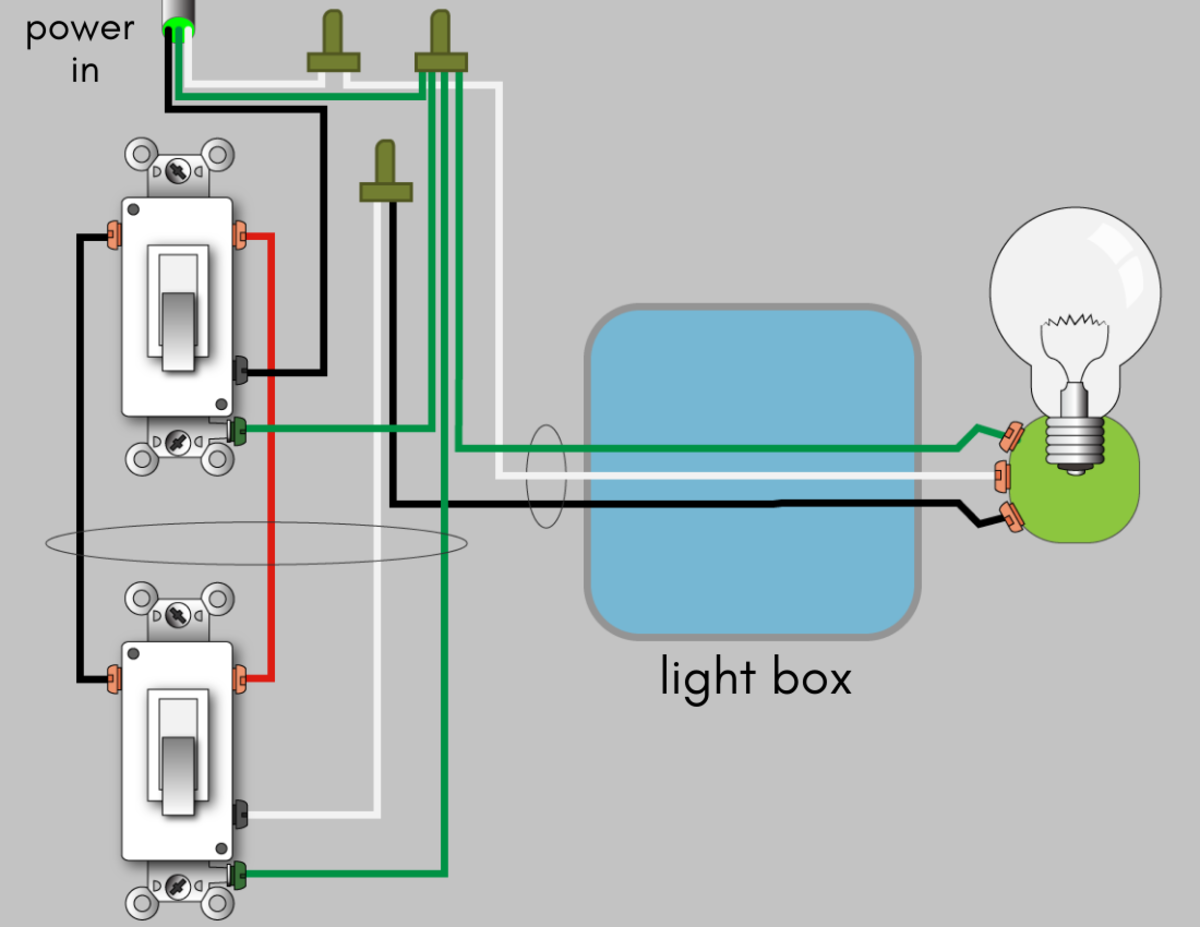

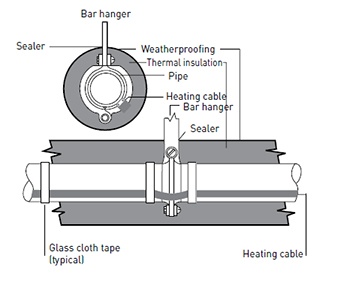

Attach the cable to the pipe leave an extra foot if at an end seal two feet if at a power connection and cut the heater cable from the reel.

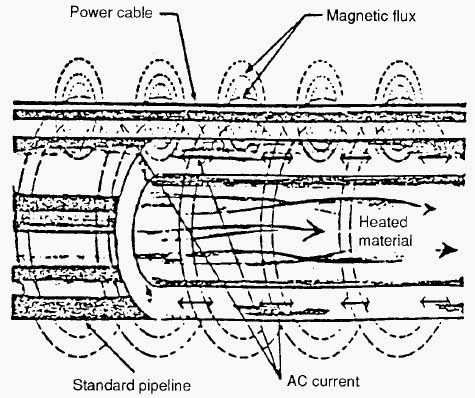

Diagram 3 wire heat trace cable. Eq 13 q ka t11 heat loss btuhr l btus and watts a comparison. It is rated for t5. Equation 13 calculates the heat loss of an entire flat area in btuhr. Trace heating cables are created by placing a semi conductive self regulating heating matrix around two bus wires one live and one neutral.

Design installation and maintenance manual industrial electric heat tracing systems. Refer to the proper. Heating cable is also referred to as heat trace cable amongst the industry or heat tape for pipes. Rewriting equation 12 the basic heat loss q can be written as.

Cable connection heating tape heat tape self regulating elsr for heat tracing heat cable heat trace trace heat heat tape termination heating cable termination electrical trace heating. This includes products such as transformers control and monitoring panels power connections heating cable end terminations and related accessories. Design guide and installation details for self regulating heating cable the rscc 2700 self regulating heat ing cable is available with either a tinned copper or stainlesssteel over shield. Install the heater cable loops on the heat sinks.

Supermec provides a complete system from design to installation commissioning and testing. Heater cable attached all along the pipe with the correct amount of heater cable pulled in loops at all heat sinks. Class ii division 2 group g. Therefore equation 13 needs a conversion factor to convert from btu to.

It is used for a wide range of applications including pipe heat tracing freeze protection viscosity control temperature process maintenance roof and gutter and much more. An electrical heat tracing system is much more than just the heating cable. 20 21 notes. Class iii division 2 areas.

Trace heating cables are constructed from thermoplastic layers containing a self regulating heating element and two adjacent bus wires. Electricity is normally sold by kilowatt hours. Heat traces it s self regulating tracers should always be selected as a first option.