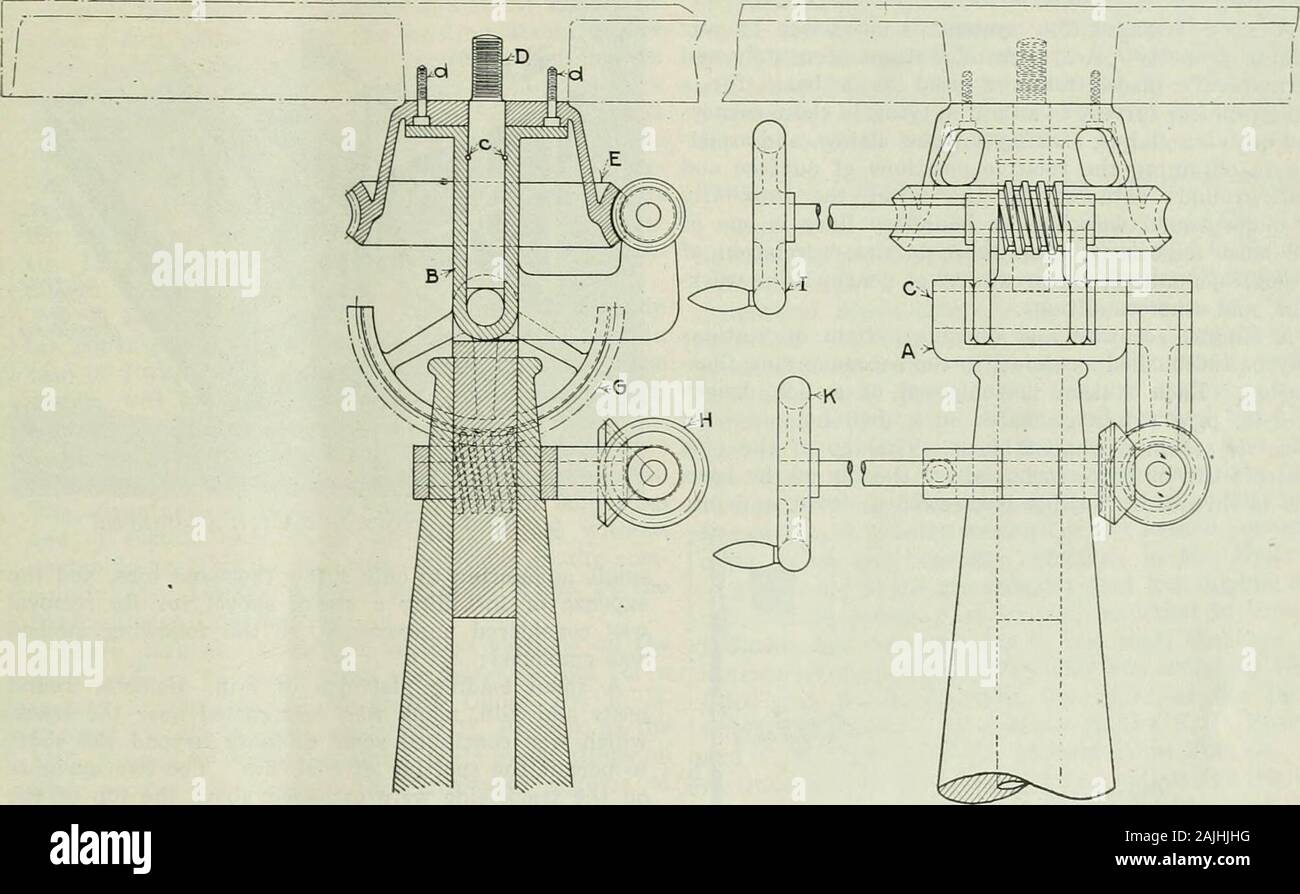

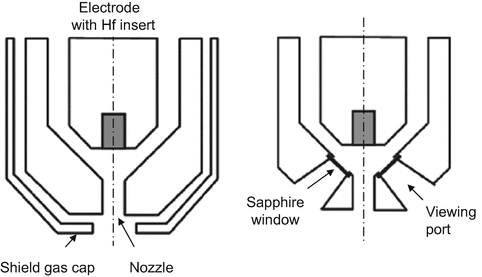

Ga Welding Torch Diagram

Oxy fuel cutting ofc is similar to ox.

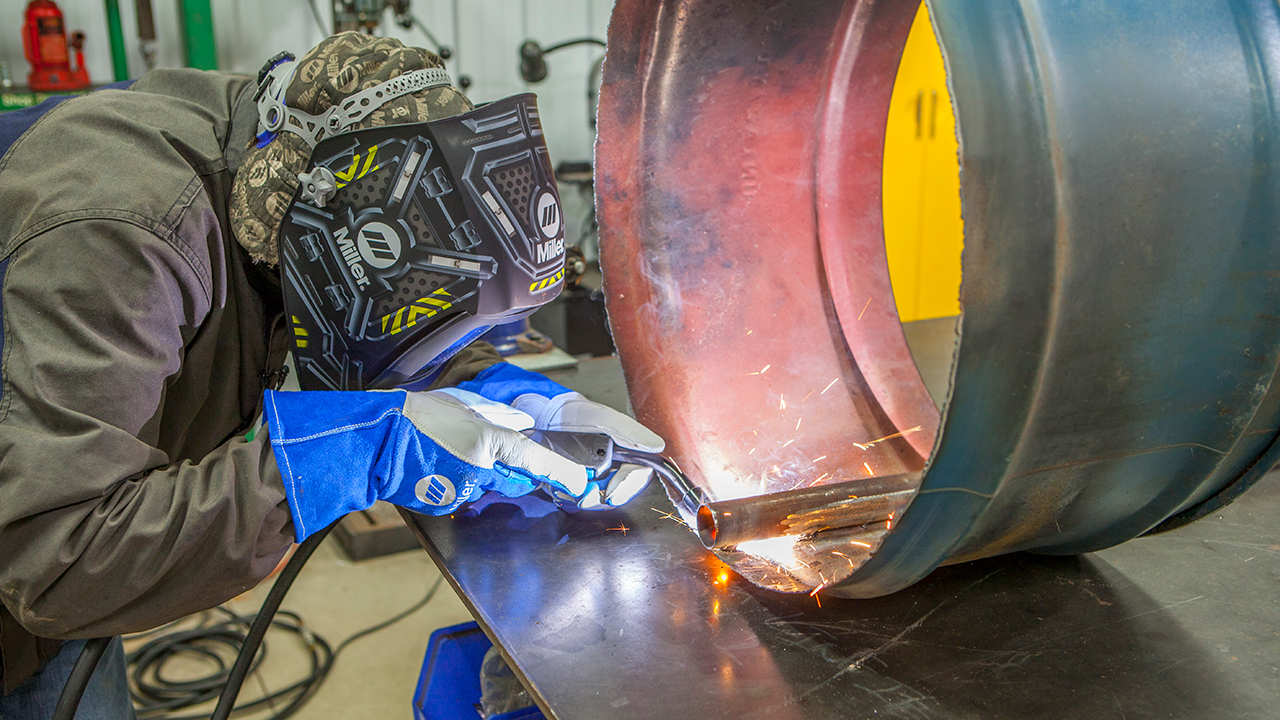

Ga welding torch diagram. Miller 023 030 035 contact tips nozzles liner and mig welding gun. Mig welding is sometimes referred to as the hot glue gun of the weldi. Mig welding is a welding process that can weld almost any metal. Apart from using hacksaw power saw chisels etc.

Between the laser and the welding torch in co 2 lasermig hybrid welding on the depth of penetration for 5005 almg alloy and has been used in the present work for the purpose of training testing and optimization of the gaann model. This is a basic guide on how to weld using a metal inert gas mig welder. Ga 21c and ga 21cm processes description mig gmaw welding air cooled gun om 1029a november 1993 eff. For metal cutting operation gas or oxygen cutting is extensively used now a days in industry.

Cant find the part youre looking for. It may not always be the best choice for weld quality but mig welding is a fast cost efficient and produces results that are more than acceptable for most manufacturing and fabrication needs. We also carry parts and accessories for brands such as miller lincoln hobart hypertherm thermal dynamics and many others as well. Along with the wire electrode a shielding gas feeds through the welding gun.

Process of gas cutting 2. After reading this article you will learn about 1. Mig welding is the awesome process of using electricity to melt and join pieces of metal together. Quality torch and regulator parts and the leader in torch and regulator rebuilding and repair.

Our site features htp america mig tig stick and spot welders plasma cutters and other htp branded parts and accessories. The results indicate that the gaann model can predict the output with reasonably good accuracy. Miller ga 20c vintage and 200 mig welding gun replacement parts and consumables. Process of gas cutting.

New welding heating tips 34 uniweld welding heating tips 31 victor welding heating tips 3 rebuilt used equipment 1 repair parts 276. Efficiency of gas cutting 3.