Halton Exhaust Hood Wiring Diagram

When the hood is elevated to the proper height install 12 threaded rod between each mounting bracket on the hood and the modified support.

Halton exhaust hood wiring diagram. Halton capture jet tm with side jet technology reduces the exhaust airflow rates required and improves the capture and containment efficiency of the hood. 10 for installation details. At this point proceed to weld exhaust duct to hood while on floor if possible. Oven wiring harness installation instructions 8 pin connector a.

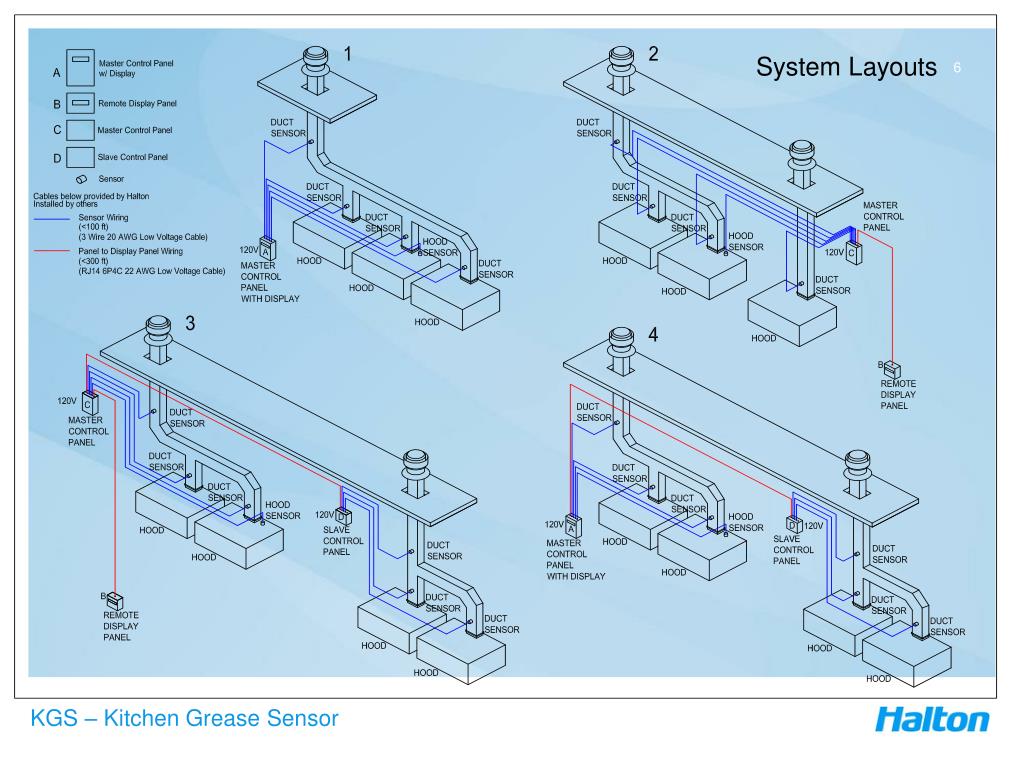

Exhaust airflows please see submittal drawings or contact the manufacturer for each hoods exhaust air flow rates. Haltons applications department determines the optimum exhaust. For halton capture jet series hoods a typical wiring diagram is shown on pg. These diagrams are current at the time of publication check the wiring diagram supplied with the motor.

Ensure the power to the oven is disconnected prior to wiring the control panel and oven. For units with exhaust fire dampers see pg. Locate the control panel at the exhaust hood and wiring diagram for the system. Micro switch 1 for supply fan shutdown in fire should be field wired to terminals nc1 brown c1 red and no1 black in the control panel.

With the hood well protected against possible scratching lift the hood into position using high lifts or equipment jacks. The device shown below in photo 1 has two taps photo 2 that are connected to the exhaust hood to monitor the differential pressure between ambient air and the exhaust plenum. Installation wiring diagram provided by certified electrician. This connection is factory wired on hood mounted systems.

Improved indoor air quality with reduced energy use. Locate the control panel at the exhaust hood and wiring diagram for the system. Review the wiring diagram and all instructions prior to beginning the process. Review the wiring diagram and all instructions prior to beginning the process.

Wiring and start up 11 wiring a licensed electrician familiar with commercial kitchen hood installation should perform wiring. Page 14 the accuflow by halton is a bluetooth equipped device intended to monitor the exhaust airflow rate of halton capture jet hoods and alarm kitchen staff if the hood is above or below design. Oven wiring harness installation instructions 8 pin connector a. The larkin wiring package requires two 2 micro switches.

Refer to the motor manufacturers data on the motor for wiring diagrams on standard frame ex e ex d etc. 9 or supply fire dampers see pg. Inst maint wiringqxd 5032008 1002 am page 6. Control panel electrical wiring diagram field wiring diagram control panel wiring diagram.

Electrical circuits should be connected according to standard switch panel wiring diagram shown on pg. Ensure the power to the oven is disconnected prior to wiring the control panel and oven. Halton capture jet kve ww operators manual. Before installing any hood system or exhaust ductwork.