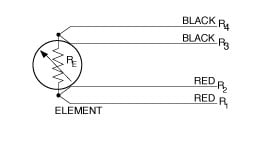

Dual Element Thermocouple Wiring Diagram

Its pretty easy to tell when youve done it wrong.

Dual element thermocouple wiring diagram. Type r thermocouple platinum rhodium 13 platinum. Any time continuous tamperature monitoring is crucial the dual element provides a backup in the event that one fails thermocouple types. A wiring diagram is a simplified conventional pictorial depiction of an electrical circuit. Omega miniature dual element thermocouple probe assemblies are manufactured using 4 conductor omegaclad wire and feature smp subminiature connectors for fast hook up.

Resistance temperature detectors rtd style h connection head assembly 4. The thermowell prevents damage to the sensor element and also allows removal of the element without spilling process fluid. Junctions are either grounded ungrounded or exposed. The type k is commonly found in nuclear applications because of its relative radiation hardness.

Omega dual element thermocouple assemblies are manufactured using 4 conductor omegaclad wire and feature rugged dtc connector terminations. 18 316 14 other diameters available upon request. When wiring with two wires first jumper across a1 and b1and a2 and b2 respectively then connect pt100 sensors and to the rtd module according to the following diagram on the left. One thing ive learned in this industry.

Rated up to 1800c 3560f sheath diameters. The type r is very similar to the type s in terms of performance. The type r is used in very high temperature applications. You wire the thermocouple directly into an.

Sheath operating temperature 2. Wiring there are 2 wiring methods for the rtd module and pt100 temperature sensors two wire and three wire connections. Rtd element type material resistance temp. The type k is the most common type of thermocouple.

It shows the parts of the circuit as simplified forms as well as the power and also signal connections in between the tools. Uses 2 sensors to allow for 2 readings of a single point common applications. Coefficient a platinumstd 100 ohms at 0oc00385 ohmohmoc b platinum 100 ohms at 0 oc00392 ohmohm c c platinum 500 ohms at 0oc00385 ohmohmoc. Installation operating and maintenance instructions thermocouple and rtd assemblies p1 thermowell use the use of a thermowell is recommended for any pressurized application.

Either 304 ss or inconel sheaths are available in sizes from 116 to 14 od with either grounded ungrounded or exposed junctions. It has a higher percentage of rhodium than the type s which makes it more expensive. 304 ss sheaths are standard with either 0062 or 0125 od. A1b1 a2b2 and c1c2.

Its inexpensive accurate reliable and has a wide temperature range.