Electrical Wire Harness Design

Learning media development lmd subject.

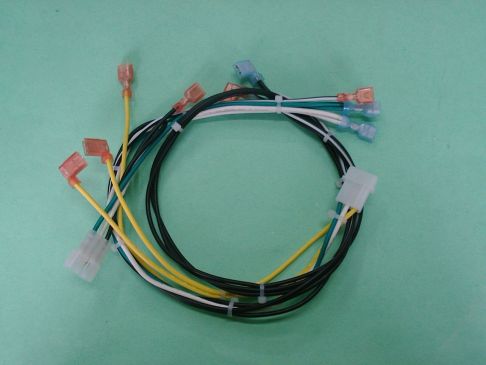

Electrical wire harness design. The cables are bound together by a durable material such as rubber vinyl electrical tape conduit a weave of extruded string or a combination thereof. This recorded seminar will show you how you can improve design productivity with. In fact the success of an application and its relationship with wires and the overall flow of current is all anchored to how well a wiring harness is designed. Developed for platforms such as aircraft automotive commercial trucks and off highway vehicles mentors electrical systems and wire harness design solutions address todays ee design complexities.

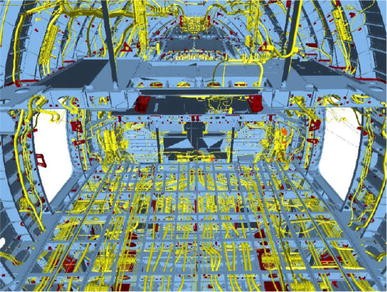

Catia electrical harness design catia v5r19 electrical harness design in this section you will look at developing a simple single branch harness. These two workbenches work together to define the harness and the bundles. Creating a wire harness with harness design author. The electrical routing tools provide smart features and functions to automate the design modification and analysis of wire harnesses.

Our deep understanding of industry challenges enables us to provide software and services that solve the most challenging problems. 1052010 92337 am. Fully associative 3d flattened harness models enabling design synchronization and concurrent engineering. Keep in mind you will be using both the electrical harness assembly and electrical harness installation workbenches.

Through this catia v5 electrical harness design online course user will gain an understanding of the user interface on catia v5 electrical harness design and how does 3d digital mock updmu space allocation plays an important role in designing harness routing. Nx offers a fully integrated 3d electrical routing and wire harness design application that allows you to design and route harnesses in complex assemblies. The biggest mistake that engineers make when designing wire harnesses is failure to control and translate the preliminary functional analytical and commercial requirements of the harness system into efficiently connected product lifecycle management methodologies and workflows claims david roach business sales manager for harness prod at eplan software services llc.